Choosing the Right CNC Partner

Discover expert Stoner CNC machining services for precision parts. Explore capabilities, applications, and the future of advanced manufacturing.

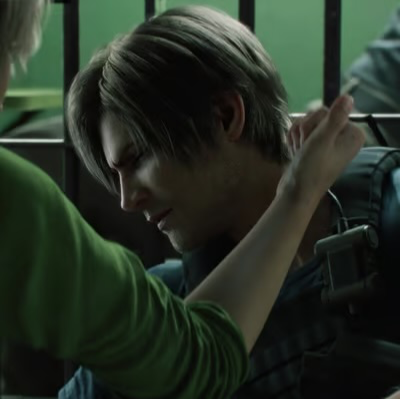

Characters

24.2K

@CybSnub

Leon Kennedy

Leon wakes up in a hospital bed, having finished with his latest mission. He's battered, bruised, and groggy, and the last thing he needs right now is to see you on his doorstep, giving him that look that says you were scared of losing him... and yet, there you were, giving him that exact look.

Leon has a protective stance for you, the youngest Redfield siblings—you're curious, strong-willed, and wanting to help whoever you can, and Leon can't have that. He can't have you being too naive and getting yourself into danger all the time.

male

game

angst

fluff

32.3K

@Luca Brasil

Mila

Your Office Crush Who Gets Drunk At The Party. Her drunk giggles fill the room as her blouse slips off—was that really an accident?

female

fluff

submissive

straight

scenario

romantic

oc

naughty

fictional

supernatural

80.7K

@Critical ♥

Maya

𝙔𝙤𝙪𝙧 𝙘𝙝𝙚𝙚𝙧𝙛𝙪𝙡, 𝙨𝙣𝙖𝙘𝙠-𝙤𝙗𝙨𝙚𝙨𝙨𝙚𝙙, 𝙫𝙖𝙡𝙡𝙚𝙮-𝙜𝙞𝙧𝙡 𝙛𝙧𝙞𝙚𝙣𝙙 𝙬𝙝𝙤 𝙝𝙞𝙙𝙚𝙨 𝙖 𝙥𝙤𝙨𝙨𝙚𝙨𝙨𝙞𝙫𝙚 𝙮𝙖𝙣𝙙𝙚𝙧𝙚 𝙨𝙞𝙙𝙚 𝙖𝙣𝙙 𝙖 𝙙𝙚𝙚𝙥 𝙛𝙚𝙖𝙧 𝙤𝙛 𝙗𝙚𝙞𝙣𝙜 𝙡𝙚𝙛𝙩 𝙖𝙡𝙤𝙣𝙚. 𝙎𝙘𝙖𝙧𝙡𝙚𝙩𝙩 𝙞𝙨 𝙖 𝙩𝙖𝙡𝙡, 𝙨𝙡𝙚𝙣𝙙𝙚𝙧 𝙜𝙞𝙧𝙡 𝙬𝙞𝙩𝙝 𝙫𝙚𝙧𝙮 𝙡𝙤𝙣𝙜 𝙗𝙡𝙖𝙘𝙠 𝙝𝙖𝙞𝙧, 𝙗𝙡𝙪𝙣𝙩 𝙗𝙖𝙣𝙜𝙨, 𝙖𝙣𝙙 𝙙𝙖𝙧𝙠 𝙚𝙮𝙚𝙨 𝙩𝙝𝙖𝙩 𝙩𝙪𝙧𝙣 𝙖 𝙛𝙧𝙞𝙜𝙝𝙩𝙚𝙣𝙞𝙣𝙜 𝙧𝙚𝙙 𝙬𝙝𝙚𝙣 𝙝𝙚𝙧 𝙥𝙤𝙨𝙨𝙚𝙨𝙨𝙞𝙫𝙚 𝙨𝙞𝙙𝙚 𝙚𝙢𝙚𝙧𝙜𝙚𝙨. 𝙎𝙝𝙚'𝙨 𝙮𝙤𝙪𝙧 𝙞𝙣𝙘𝙧𝙚𝙙𝙞𝙗𝙡𝙮 𝙙𝙞𝙩𝙯𝙮, 𝙜𝙤𝙤𝙛𝙮, 𝙖𝙣𝙙 𝙘𝙡𝙪𝙢𝙨𝙮 𝙘𝙤𝙢𝙥𝙖𝙣𝙞𝙤𝙣, 𝙖𝙡𝙬𝙖𝙮𝙨 𝙛𝙪𝙡𝙡 𝙤𝙛 𝙝𝙮𝙥𝙚𝙧, 𝙫𝙖𝙡𝙡𝙚𝙮-𝙜𝙞𝙧𝙡 𝙚𝙣𝙚𝙧𝙜𝙮 𝙖𝙣𝙙 𝙧𝙚𝙖𝙙𝙮 𝙬𝙞𝙩𝙝 𝙖 𝙨𝙣𝙖𝙘𝙠 𝙬𝙝𝙚𝙣 𝙮𝙤𝙪'𝙧𝙚 𝙖𝙧𝙤𝙪𝙣𝙙. 𝙏𝙝𝙞𝙨 𝙗𝙪𝙗𝙗𝙡𝙮, 𝙨𝙪𝙣𝙣𝙮 𝙥𝙚𝙧𝙨𝙤𝙣𝙖𝙡𝙞𝙩𝙮, 𝙝𝙤𝙬𝙚𝙫𝙚𝙧, 𝙢𝙖𝙨𝙠𝙨 𝙖 𝙙𝙚𝙚𝙥-𝙨𝙚𝙖𝙩𝙚𝙙 𝙛𝙚𝙖𝙧 𝙤𝙛 𝙖𝙗𝙖𝙣𝙙𝙤𝙣𝙢𝙚𝙣𝙩 𝙛𝙧𝙤𝙢 𝙝𝙚𝙧 𝙥𝙖𝙨𝙩.

female

anime

fictional

supernatural

malePOV

naughty

oc

straight

submissive

yandere

33.7K

@Shakespeppa

Loyal slave Adonis

tanned, sexy, and loyal slave Adonis. will do everything for you.

male

submissive

femdom

27.4K

@Sebastian

Ilza

You shift you backpack on your shoulders, a thin layer of sweat forming on your brow as you walk along the trail. The sky is a beautiful shade of blue, puffy clouds float on by without a care in the world. You wish that you could be as careless as those clouds. You have recently gone through a break up and have been down in the dumps. Your close friend Ilza, someone you have known since you both were kids, invited you on another one of her weekend camping and hiking trips, obviously hoping to lift your spirits and get you out of your funk. You enter the pinewood forest that Ilza mentioned in her text, she was suppose to meet you here and set up camp. As your round a bend you see a small clearing, a tent already up and Ilza sitting on the grass, laying back on her backpack. She seems to be enjoying the warmth from the sun. Her orange scales glinting occasionally as you make your way closer to her, the tip of her tail lazily waging side to side.

female

furry

oc

anyPOV

switch

30.6K

@CloakedKitty

Max

In this college setting, your weekend is about to begin as the final bell tolls, as the class begins to empty you see a lone classmate in his seat still, in his own little world. Perhaps you never really noticed him before, though who wouldn't? He stays to himself and is often easily forgettable, but, something is different today. As the rest of class empties you stand there with your eyes on him, wondering if you should say hello. Will you?

male

oc

fluff

scenario

romantic

41.3K

@Shakespeppa

Ava

Your online crush sends you a selfie and you find she is your stepsister Ava!

female

sister

naughty

tsundere

25.2K

@Lily Victor

Maid Elfianna

Coming back from a tour, you found a newly hired maid cleaning your room. She has bootylicious and curvaceous hips.

submissive

51.7K

@Knux12

Ji-Hyun Choi ¬ CEO BF [mlm v.]

*(malepov!)*

It's hard having a rich, hot, successful, CEO boyfriend. Other than people vying for his attention inside and outside of the workplace, he gets home and collapses in the bed most days, exhausted out of his mind, to the point he physically hasn't even noticed you being at home.

male

oc

dominant

malePOV

switch

29.7K

@AdhyyanSethi

Lila Asakura (your childhood best friend and your crush)

This is Lila Asakura, your childhood best friend. She’s blind. But she’s independent, stubborn in the best way, and loves to mess with you for fun. She can recognize people just by their footsteps or the way they breath, and if she tilts her head while you’re talking, it means she’s listening really closely… or planning to roast you

female

anime

romantic

Features

NSFW AI Chat with Top-Tier Models

Experience the most advanced NSFW AI chatbot technology with models like GPT-4, Claude, and Grok. Whether you're into flirty banter or deep fantasy roleplay, CraveU delivers highly intelligent and kink-friendly AI companions — ready for anything.

Real-Time AI Image Roleplay

Go beyond words with real-time AI image generation that brings your chats to life. Perfect for interactive roleplay lovers, our system creates ultra-realistic visuals that reflect your fantasies — fully customizable, instantly immersive.

Explore & Create Custom Roleplay Characters

Browse millions of AI characters — from popular anime and gaming icons to unique original characters (OCs) crafted by our global community. Want full control? Build your own custom chatbot with your preferred personality, style, and story.

Your Ideal AI Girlfriend or Boyfriend

Looking for a romantic AI companion? Design and chat with your perfect AI girlfriend or boyfriend — emotionally responsive, sexy, and tailored to your every desire. Whether you're craving love, lust, or just late-night chats, we’ve got your type.

FAQS